Data acquisition system

A data acquisition system is a system designed to record and possibly post-process the measurements of one or more physical quantities.

Speaking of systems, we mean a set of instruments that, when properly connected and set, realize one or more measurement chains. Essential for these systems is that the measurements are recorded on supports (usually sql / no-sql databases) sufficiently stable to have the time to analyze them, or at the very least, be kept for documentary purposes for an indefinite time.

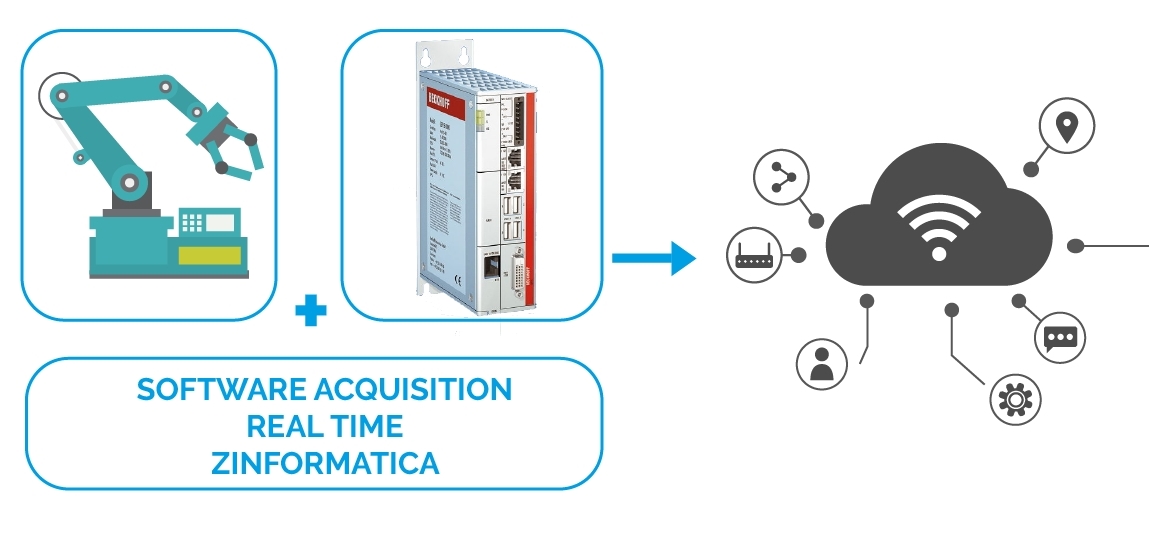

Real time data acquisitions

IOTAR ACQUISITION SW is a Real-time Data Acquisition System from PLCs for data collection (for example pieces produced, machine status, downtime, temperature, speed, A / D signals, pressures, torque values, high speed signals, etc.) coming from production machines; customized systems suitable for existing industrial infrastructures.All data is collected by the PLC with the IOTAR Acquisition SW system in real time in SQL or NO-SQL database both in private and public Clouds. Through a functional module our solutions allow to move and synchronize enormous amounts of data in a bidirectional way (thanks to an already tested module it is possible to move, through the simple drag & drop, the data from the PLC to the Database).

Through our IOTAR Acquisition SW data acquisition systems it is possible:

- Monitoring machines and consumption resources;

- The summary of labor times (via industrial terminals, barcode, RFID, NFC, badge);

- Supervision of production lines, with time and machine stop detection (also with the innovative IOTAR Web App);

- A more effective planning, programming and scheduling of production;

-The management of design and production orders thanks to the integration with ERP (Enterprise Resource Planning);

- The calculation of production efficiency;

- A careful quality control;

- End of line labeling;

- Management and maintenance scheduling;

-A more accurate warehouse and logistics management with goods traceability;

- …

On request, for particular integrations with machines (PLC - Digital Signals - Piece Counters - Alarms) we create highly customized software (we prefer Beckhoff technologies, but we are able to adapt to the customer's structure) using VB, C ++, C # technologies .NET and on IOT.

IOTAR SUITE

Discover all the potential of IOTAR SUITE the solution of modular products that give you the possibility to acquire data from the systems and to monitor your production from any mobile device.

Production, factory planning, assembly, work safety, digital testing and prototyping, remote maintenance are just some of the cases of use possible with the IOTAR suite.